Why Are Chassis Components Crucial for Stability?

The chassis of a vehicle serves as its backbone, supporting essential components like the engine, transmission, suspension, and wheels. These components are responsible for the vehicle's stability, handling, and overall safety on the road. The chassis not only provides the framework for the vehicle’s structure but also absorbs and distributes forces encountered during driving. Understanding why chassis components are so vital to vehicle stability is key to appreciating how the vehicle performs and ensures a smooth, safe ride. In this article, we will dive into the role of chassis components and why they are crucial for maintaining stability.

The Role of Chassis Components in Vehicle Stability

Chassis components contribute directly to how a vehicle handles, responds to road conditions, and remains stable during various driving scenarios. They are designed to manage the vehicle's weight distribution, absorb shocks, and provide precise control. Without these components, the vehicle would be unable to maintain its stability, particularly during high-speed driving or when navigating rough terrains.

The Chassis Frame: The Foundation of Stability

The chassis frame is the primary structure of the vehicle that supports all major components, such as the engine, wheels, and suspension system. It must be strong, yet flexible enough to absorb impacts without compromising the integrity of the vehicle. The frame is designed to evenly distribute forces, including those from acceleration, braking, and cornering.

A well-engineered chassis frame ensures that the vehicle remains balanced and stable under various conditions. If the frame is weakened due to poor design or damage, the vehicle's overall stability can be compromised, leading to handling issues, increased risk of rollovers, and a reduction in safety.

Suspension System: Ensuring Smooth Ride and Stability

The suspension system plays a crucial role in vehicle stability by maintaining tire contact with the road, reducing the impact of bumps, and preventing excessive body roll. Key components of the suspension system include shock absorbers, struts, springs, and control arms. These parts work together to absorb shocks and vibrations from the road, ensuring a smooth and controlled ride.

A properly functioning suspension system ensures that the vehicle remains stable, even during sharp turns or when driving over uneven surfaces. Worn-out suspension components, such as faulty shock absorbers or broken springs, can lead to poor handling, reduced tire contact with the road, and increased risk of accidents.

Steering System: Vital for Control and Stability

The steering system directly influences the vehicle’s ability to navigate corners, make turns, and maintain control at high speeds. A critical part of the chassis, the steering system ensures that the driver can guide the vehicle safely, especially when making tight turns or avoiding obstacles. The steering rack, tie rods, and power steering pump work together to provide responsive handling and stability.

A malfunction in the steering system, such as misalignment or worn-out steering components, can result in poor vehicle handling, causing the car to drift or pull to one side. This compromises the stability and control of the vehicle, increasing the risk of accidents.

Axles and Differential: Power and Balance

Axles are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move. The differential, on the other hand, allows the wheels to rotate at different speeds while maintaining balance during turns. Together, these components ensure that the vehicle remains stable by distributing power evenly and preventing loss of traction.

Damaged or worn-out axles and differentials can cause instability, making it difficult to control the vehicle. For example, if the differential is not functioning correctly, it can lead to uneven wheel rotation, resulting in poor traction and handling, especially on slippery or uneven surfaces.

Why Chassis Components Affect Handling and Cornering

Cornering stability is one of the most critical aspects of a vehicle’s performance, particularly when driving at higher speeds. Chassis components play a vital role in maintaining balance and preventing excessive body roll or skidding during turns.

Anti-Roll Bars: Reducing Body Roll

Anti-roll bars, also known as sway bars, are essential chassis components that help reduce body roll when cornering. They work by connecting the left and right sides of the suspension, distributing the force more evenly across both sides of the vehicle. This helps prevent excessive leaning or tilting, especially during sharp turns, which can affect the stability and handling of the vehicle.

By keeping the vehicle level, anti-roll bars improve grip and control during cornering, making the driving experience smoother and safer. Without them, the vehicle may experience greater body roll, which compromises stability and can lead to accidents, particularly when making sudden turns or sharp lane changes.

Tire Alignment and Its Impact on Stability

Proper tire alignment is crucial for maintaining vehicle stability. Misaligned wheels cause uneven tire wear and reduce the vehicle’s ability to maintain a straight path on the road. This can lead to instability, especially when driving at higher speeds or in windy conditions.

Regularly checking and maintaining proper wheel alignment ensures that the tires are positioned correctly, improving traction and stability. Misalignment can also lead to poor fuel efficiency, as the vehicle requires more effort to maintain a straight path.

Impact of Road Conditions on Chassis Stability

External factors such as road conditions significantly affect the performance of chassis components. Poorly maintained roads with potholes, bumps, or uneven surfaces can put a strain on the suspension system, axle, and frame, accelerating wear and tear. Driving on rough terrain or in inclement weather can also impact the stability of the chassis, causing parts to deteriorate faster.

Driving on Uneven Roads

Rough roads and potholes can cause chassis components to wear out more quickly, particularly the suspension and axles. The shocks from hitting bumps or potholes create repetitive stress, which can lead to cracks or damage in key components like shock absorbers, suspension springs, and control arms.

A damaged suspension system caused by driving on poor roads can reduce the vehicle’s ability to absorb shocks and maintain stability, leading to a rougher ride and less precise handling.

Weather Conditions and Their Effect on Chassis Parts

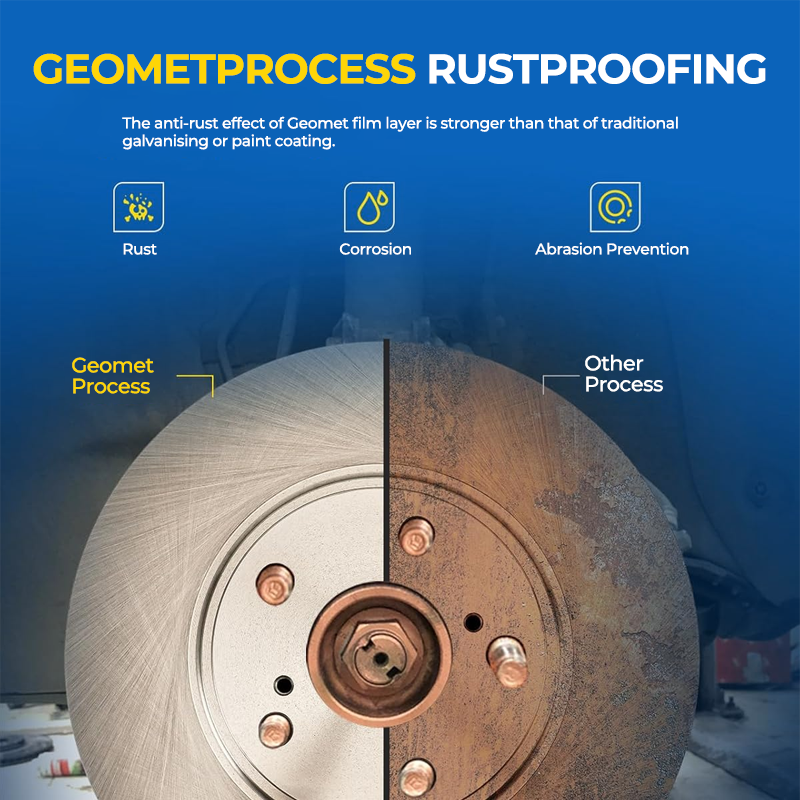

Harsh weather conditions, such as extreme heat, cold, or moisture, can accelerate the wear of chassis components. For example, road salt used in winter conditions can lead to corrosion in metal parts of the chassis, weakening their structural integrity. Similarly, exposure to extreme heat can cause rubber components, such as bushings and seals, to dry out and crack.

Regular maintenance, including washing the vehicle to remove road salt and applying rust prevention treatments, can help protect the chassis from weather-related wear and ensure its continued stability.

FAQ

What happens if chassis components are not maintained properly?

If chassis components are not properly maintained, the vehicle's stability, handling, and overall safety can be compromised. Worn suspension parts, misaligned wheels, or damaged axles can lead to poor handling, reduced control, and increased risk of accidents.

How can I tell if my suspension system is damaged?

Signs of a damaged suspension system include excessive bouncing, uneven tire wear, poor handling, and difficulty steering. If you notice these symptoms, it’s essential to have the suspension system inspected and repaired by a professional.

Can driving habits affect chassis stability?

Yes, aggressive driving, such as hard braking, sharp turns, and rapid acceleration, can place additional strain on chassis components, leading to premature wear. Smooth driving habits can help maintain the health of the chassis and improve overall vehicle stability.

How often should I check my chassis components for wear?

It’s recommended to have your chassis components inspected at least once a year or every 12,000 miles. However, if you notice any signs of instability, poor handling, or unusual noises, you should have them checked immediately.